If the screen becomes eco-friendly: the KIT project

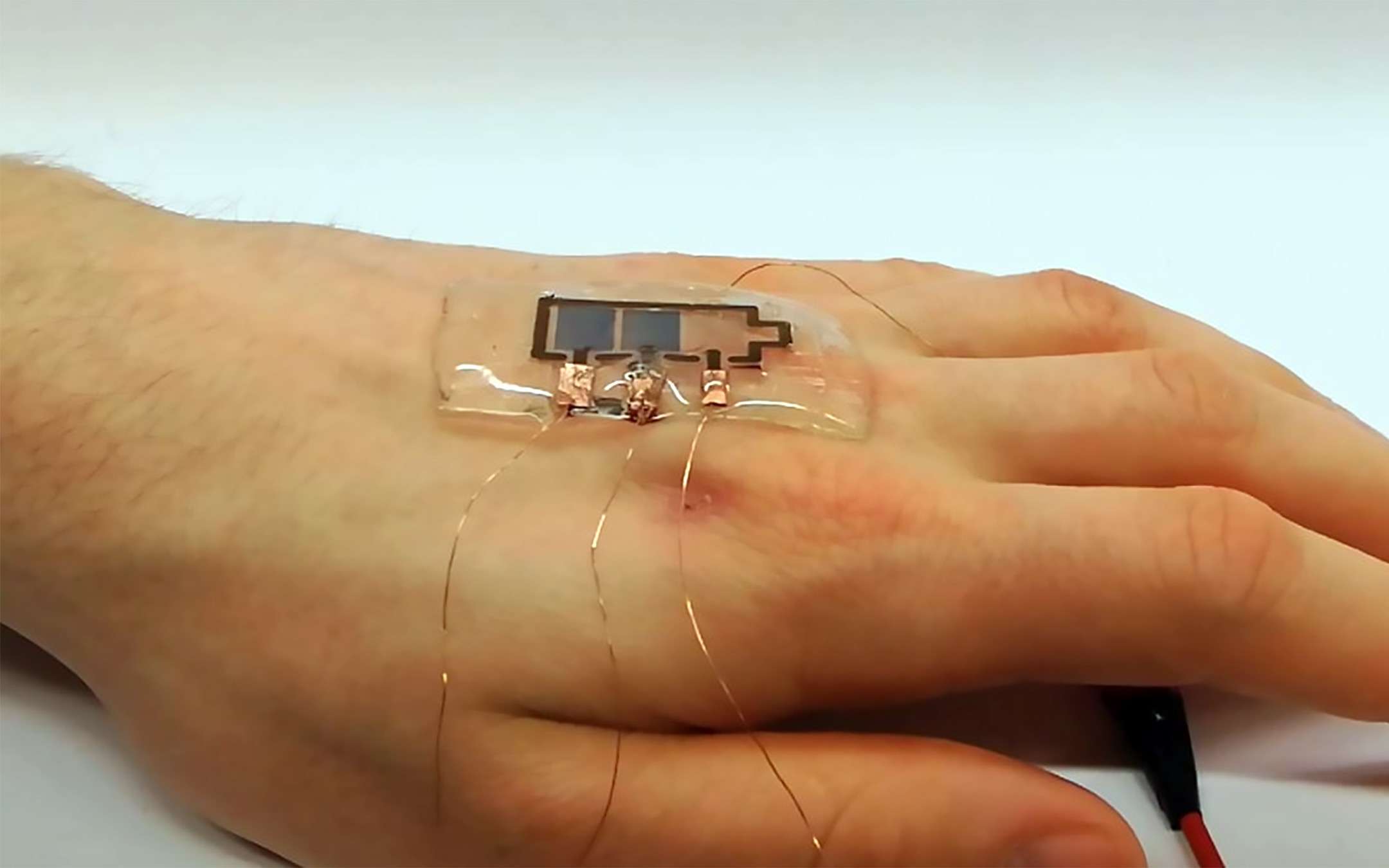

Their structure also makes them flexible and potentially applicable (as you can see in the opening image) to the skin: a type of innovation that opens the door to a new conception of the term "wearable device".The advantages do not end there: energy consumption it is reduced to a minimum and the technology used allows them to be integrated into devices in a simpler way than with traditional LEDs, LCDs or e-ink. Construction costs are also contained by leveraging a method comparable to that of inkjet printing. The surface obtained is enclosed in a protective layer consisting of a particular "gelatin". These are the words of Manuel Pietsch, researcher and author of the publication.

For the first time, we have shown that it is possible to produce sustainable displays based largely on natural materials with the help of industrial production methods. Once used, they do not become electronic garbage, but can be composted. In addition to recycling and reuse, this could help reduce or completely eliminate some of the impact of electronic waste.

Anyway it is good to specify that we will not see this type of display on smartphone, tablet or computer. Their nature makes them suitable for use on equipment with a short life cycle, such as disposable medical devices for monitoring vital parameters or on food packaging to certify their correct conservation. At the moment, everything is to be considered a sort of prototype, no timing has been disclosed for a possible commercial debut.

Source: Karlsruhe Institute of Technology